Researchers have confirmed {that a} metallic alloy of chromium, cobalt and nickel is formally the hardest materials on Earth — greater than 100 instances harder than the marvel materials graphene (opens in new tab).

In a brand new examine printed Dec. 1 within the journal Science (opens in new tab), researchers subjected the ultra-tough alloy to extraordinarily chilly temperatures, with the intention to check how fracture-resistant the fabric is. Scientists have recognized for years that this alloy is one robust cookie — nevertheless, to the staff’s shock, the alloy solely grew to become harder and extra immune to cracks as temperatures plummeted.

This super-resistance to fracture is in stark distinction to most supplies, which solely change into extra brittle in freezing temperatures, in line with the examine authors.

“Folks speak in regards to the toughness of graphene, and that’s measured at simply 4 megapascals per meter,” examine co-author Robert Ritchie (opens in new tab), a professor of engineering on the College of California Berkeley and senior college scientist on the Lawrence Berkeley Nationwide Laboratory, informed Stay Science. “The toughness of aluminum alloys utilized in plane is 35 megapascals per meter. This materials has a toughness of 450 to 500 megapascals per meter… these are mind-boggling numbers.”

The potential purposes of such a troublesome materials vary from space infrastructure to fracture-resistant containers for clear vitality makes use of right here on Earth. Nevertheless, Ritchie famous, two of the alloy’s three parts (nickel and cobalt) are prohibitively costly, limiting the alloy’s usefulness to the laboratory for the foreseeable future.

Unusual alloy

The chromium (opens in new tab), cobalt (opens in new tab)and nickel (opens in new tab) alloy is an instance of a excessive entropy alloy (HEA). Not like most alloys, that are made predominantly of 1 ingredient with decrease quantities of extra parts added, HEAs are made from an equal combine of every constituent ingredient.

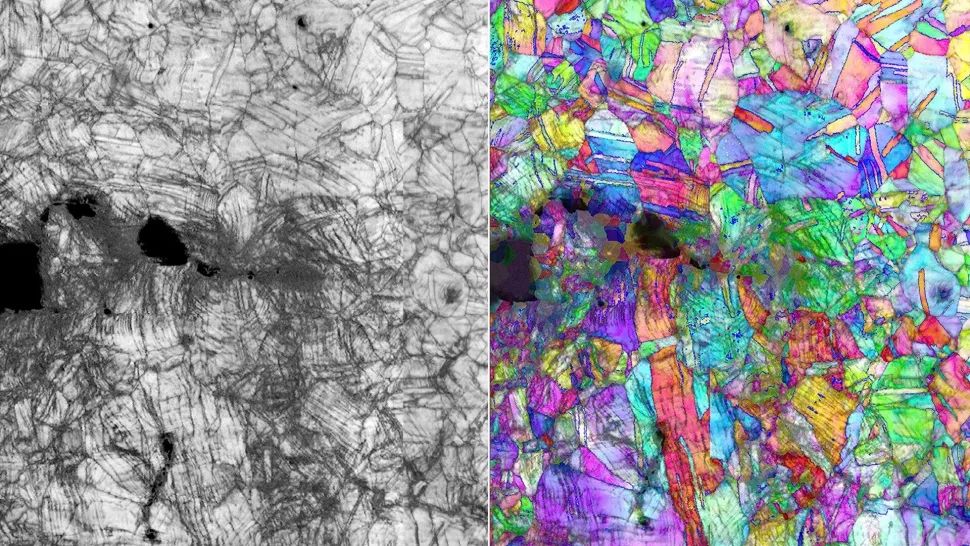

This HEA is extraordinarily malleable, or ductile, which means it could possibly bend beneath strain to face up to fracturing, in line with the examine authors. A number of quirks of the alloy’s molecular construction make it so terribly malleable. One key mechanism, for instance, causes atoms throughout the alloy to dislocate beneath strain, permitting them to shear over each other. This, together with varied different mechanisms, enable the fabric to maintain deforming as strain will increase, with out fracturing or breaking.

“Every considered one of these mechanisms kicks in at a later stage whenever you enhance the pressure on the fabric and that is the proper recipe for top toughness,” Ritchie added. “What’s outstanding is these mechanisms get simpler in colder temperatures.”

The researchers initially examined the alloy’s toughness by exposing it to liquid nitrogen at temperatures of round minus 321 levels Fahrenheit (minus 196 levels Celsius). When the alloy’s toughness solely improved, the staff questioned how a lot additional they might push the fabric’s limits.

Dong Liu (opens in new tab), a physicist at Bristol College in England, and colleagues designed an experiment to show the alloy to liquid helium, which might cool to super-frigid temperatures of minus 424 F (minus 253 C). The staff then watched neutrons scatter off the fabric in a course of referred to as neutron diffraction to see into the construction of the alloy and see how cracks shaped as strain elevated.

The experiment confirmed that when it got here to toughness, the alloy blew graphene out of the water.

“Graphene may be very excessive power, however it would not have any injury tolerance,” Liu informed Stay Science. “It is very brittle and shatters similar to a mug you throw on the ground that shatters into items.”

One other downside of graphene is that its excessive power solely holds at exceptionally small, nanometer-level scales, Liu added. In the meantime, the samples of chromium, cobalt and nickel alloy examined by Liu and her staff had been cigarette-pack-size, which means the HEA maintained its toughness on the scale of on a regular basis objects.

Supplies of the longer term

Whereas extra testing is required earlier than this materials will be virtually utilized, Liu is optimistic that the alloy may very well be used for a lot of initiatives, each in space and on Earth. For instance, the HEA may very well be utilized in hydrogen (opens in new tab)storage containers that might make environmentally pleasant hydrogen-powered automobiles extra possible.

“In case you drive a automotive with a hydrogen vessel constructed from one thing very brittle you are primarily carrying a bomb round with you,” Liu stated. “However not with this materials.”

Ritchie, in the meantime, is cautious in suggesting potential purposes of the alloy, as shifting materials from the lab to the “actual world” requires a variety of data and time, whereas the prices of nickel and cobalt stay prohibitively excessive. Nevertheless, he’s eager about creating recipes for brand spanking new alloys that may very well be simply as robust, utilizing completely different parts.

“There’s 50 usable parts within the periodic desk,” Ritchie stated. “Taking combos of three, 5 or seven of them means there are hundreds of thousands of recent alloys.”

Initially printed on LiveScience.com (opens in new tab).